In the globe of electronics and modern technology, the relevance of printed circuit boards (PCBs) can not be overemphasized. A PCB, frequently referred to as a circuit board, supplies the necessary structure for attaching various electronic parts via conductive tracks etched onto non-conductive substrates. Amongst the many types of PCBs, the rigid-flex circuit boards stand out as a remarkable development.

The production of PCBs, especially in high-density interconnect (HDI) setups, has actually evolved as the demand for smaller, quicker, and more effective electronics boosts. HDI PCBs include finer lines and rooms, as well as smaller vias, which permit higher part density. This is particularly important in today's hectic tech landscape where efficiency renovations are consistently sought. To make these innovative boards, companies commonly utilize advanced techniques such as microvia technology, which involves developing really little vias with laser drilling methods. The benefits of microvias consist of boosted signal speed and decreased electromagnetic disturbance, consequently improving the overall capability of the electronic gadgets they support.

Joint ventures with printed circuit manufacturers are critical in making sure that PCB designs shift smoothly from conceptual stages to real products. These manufacturers concentrate on various aspects, consisting of PCB assembly and fabrication. They utilize products like FR-4, a flame-retardant epoxy resin, which is commonly pertained to for its balance of efficiency and cost-effectiveness. In the world of high-performance applications, variants such as Rogers material, Megtron 6, and Megtron 7 are regularly used for their remarkable dielectric residential properties and high-frequency performance. As a result, printed motherboard assembly (PCBA) becomes an important action in the process where numerous components are soldered onto the PCB in accurate arrangements to guarantee optimum procedure.

Quick turn-around PCB prototyping services have actually gained popularity as businesses strive to bring their products to market swiftly. This dexterous manufacturing technique enables companies to examine and confirm their styles before dedicating to full production runs. Such prototyping is vital in minimizing time-to-market and enables iterative enhancements based on initial screening outcomes. Suppliers offer flexible alternatives for both high-volume and low-volume orders to suit diverse manufacturing needs. In addition, with the raising schedule of fast-turn PCB services, the obstacles to prototype growth have actually been dramatically decreased, making it possible for an environment of development.

Flexible printed circuit boards (FPCBs) are one more remarkable category that has garnered attention due to their unique capabilities. These boards are created to be ultra-thin and light-weight, supplying the capacity to flex, fold, or twist without endangering efficiency.

Numerous manufacturers concentrate on producing flexible circuits, frequently incorporating innovative products and production strategies to boost efficiency and dependability. Thermal management, as an example, plays an essential role in PCB design, specifically in electronic items that run under high tons. Engineers have to consider products with excellent thermal conductivity, such as heavy copper PCBs, which assist dissipate heat efficiently. In addition, advancements like the back drill process are utilized to maximize signal stability by getting rid of excess material around vias, thus removing the capacity for signal degradation.

The understanding of printed circuit board design is essential for designers and item designers. Finding out about different facets such as circuit card assembly, which includes the process of soldering parts onto a PCB, can significantly affect completion item's quality. Efficient design methods make certain that electrical pathways are enhanced and that the overall design lessens disturbance, therefore enhancing life expectancies and performance. Furthermore, using tools and software application created for PCB design and simulation can substantially simplify the design process, enabling developers to rapidly change prototypes based on testing outcomes.

Variations in PCB types such as 2-layer, 4-layer, and multi-layer boards are each suited to specific applications based on their complexity and the variety of parts that require to be integrated. Four-layer PCBs supply enhanced routing capacities, important for more innovative electronics. These boards assist in managing signal stability and offer ample room to path traces extra successfully, ensuring more reputable efficiency in whatever from smartphones to complicated commercial devices.

Contract PCB assembly services have actually become a crucial resource for companies doing not have the in-house abilities to take care of complex assembly procedures. These services usually include thorough support ranging from design appointment to full-scale production, supplying organizations with the flexibility they need to fulfill varying needs. By partnering with recognized manufacturers, services can utilize experience in areas such as HDI designs, microvias, and multilayer PCBs, consequently increasing their item offerings without investing heavily in devices and labor.

Picking the appropriate products for PCB production is essential, and factors to consider frequently consist of the ecological criteria applicable to their use, including UL ratings, such as 94V-0, which concerns fire retardancy. Manufacturers need to remain notified regarding conformity guidelines to make sure that their items meet security requirements while likewise carrying out efficiently in their intended application environments.

The integration of superhigh frequency (RF) modern technology right into PCBs is one more location seeing raised importance, especially with the surge of cordless communication devices. RF PCBs must be meticulously made, with factors to consider for resistance control and reduced signal loss due to the high frequencies entailed. This field of expertise needs knowledge of RF circuit design and might involve in-depth electromagnetic simulations as engineers function to achieve optimum performance in compact forms.

As technology remains to evolve, manufacturers are significantly embracing automation and progressed fabrication processes to boost effectiveness. Technologies such as automated optical evaluation (AOI) and surface install modern technology (SMT) are now standard methods, permitting for high-speed assembly and constant quality assurance. Developments in PCB manufacturing additionally prolong to brand-new materials and methods, such as using embedded technology where parts are embedded directly within the layers of the PCB, better saving area and boosting efficiency.

Whether with PCBA, flexible circuits, or fast-turn prototypes, the materials, procedures, and designs associated with PCBs are essential in shaping the future of electronic devices. With the ever-increasing intricacy of circuits and the demand for effective, high-performance solutions, the PCB sector remains a foundation of technological progress, driving the means we communicate with tools and eventually attaching our digital and physical worlds.

Discover pcb fabrication assembly the vital function of printed circuit boards (PCBs) in modern electronics, from cutting-edge rigid-flex styles to high-density interconnects and fast-turn prototyping services, and discover just how these innovations are shaping the future of tools we utilize daily.

Angus T. Jones Then & Now!

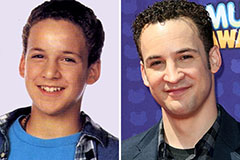

Angus T. Jones Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Anthony Michael Hall Then & Now!

Anthony Michael Hall Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!